This project started in January 2012 with the aim of recreating the alloy upper crankcase of the V12 engine fitted to the Rolls-Royce Phantom III.

The following pages give a background to the processes involved in this immensely complicated operation.

This page lists the various stages in the project, each of which has a thumbnail image on the right of the screen.

April & May 2012

Preliminary design and CAD development. |

|

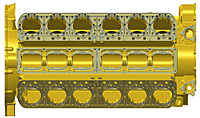

June 2012

Longitudinal sections. |

|

June 2012

Lateral sections and the sectioning of an original crankcase. |

|

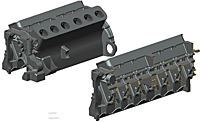

July 2012

Audit of the CAD model. |

|

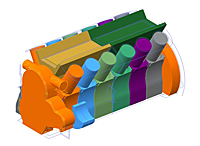

August 2012

Semi-transparent rendering of the model in preparation for pattern tooling design. |

|

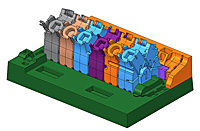

August 2012

Creation of a model for the tooling pack. |

|

September, October & November 2012

Manufacturing the tools.

|

|

December 2012

Assembling the sand cores into the core box ready for casting. |

|

December 2012

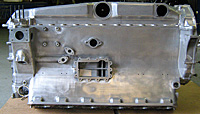

Casting the first crankcase. |

|

January & February 2013

Audit, mark-up and NDT inspection of the prototype casting.

Preparation of tooling fixtures and machining operation procedures. |

|

May 2013

Production starts for casting the engine blocks. |

|

June 2013

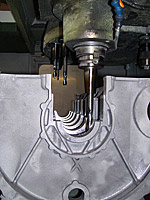

Machining commences: phase 1 on a 3-axis machine followed by the complicated work on a 5-axis machine. |

|

July to October 2013

An immense amount of detailed background checking at each stage of the 5-axis machining process to ensure reality meets expectation. Trial fitting up of components, line boring of the crankshaft and camshaft.

The first completely finished production block was despateched on Friday, 4th October. |

|

November 2013 to July 2015

The first block was built up into a complete engine, installed in the car and is running succesfully.

New blocks have been sold into the UK, USA and Australia.

|

|

| |

|

© Copyright 2011-2015: Phantom Engineering Limited.